Top 5 Innovations in Automotive Manufacturing

Explore the top five game-changing innovations and practices shaping the world of automotive manufacturing.

Driving the future of the automotive world, the rise of groundbreaking automotive manufacturing innovations have been nothing short of a revolution. These trailblazing updates in the manufacturing sector have fundamentally reshaped car production, turning the traditional process on its head and setting the stage for an exciting new era in automobile history. This piece will delve into the top five innovations that are launching the industry straight into the future.

Automotive Manufacturing Innovations: A Revolution on Wheels

From heightened digital integration and automation to sustainable technology and advanced materials, the industry is in the midst of a significant transformation. These innovations highlight how manufacturers are actively striving to improve performance, increase efficiency, reduce costs, enhance sustainability, and elevate user experience in a way never witnessed before.

Table of Contents

- The Enthralling Automation in Manufacturing

- 3D Printing: Redefining Prototyping and production

- Artificial Intelligence: The Game Changer of the Automotive Industry

- Lightweight Materials: Uplifting Automotive Efficiency

- Green Manufacturing: The Drive Towards A Sustainable Future

The Enthralling Automation in Manufacturing

Automation has undoubtedly unleashed an era of unprecedented convenience and accuracy in manufacturing. More than ever before, automotive producers rely on sophisticated machinery to carry out intricate tasks, formerly performed manually, with astonishing precision. This not only accelerates production but also minimizes human errors and enhances product quality. The advent of robotics and computer-aided systems has, particularly, simplified complex and repetitive tasks, ensuring factory floors operate more fluidly. Additionally, automation has unquestionably contributed to providing safer working conditions, as machines take over accident-prone functions.

A Case in Point: The Assembly Line Robots

The widespread deployment of assembly line robots in car manufacturing facilities is a testament to automation's pervasiveness. These automated marvels have largely replaced humans in working stations, carefully assembling various vehicle components in sync with their fellow robotic arms. From welding and painting automotive bodies to meticulously inspecting the end products, their roles are diverse but vital.

3D Printing: Redefining Prototyping and production

While 3D printing is not a new innovation, its application in the automotive manufacturing sector has witnessed a significant surge in recent years. The technology, also known as additive manufacturing, enables manufacturers to create intricate parts and complex shapes that would otherwise be challenging or expensive using traditional methods. The ultimate benefit? Time and cost efficiency.

- Prototype Development: Car manufacturers are utilizing 3D printers to produce prototype parts, accelerating the design-to-production process. This use of rapid prototyping allows for efficient testing and modifications before the final manufacturing process.

- On-Demand Production: As the technology improves and becomes more affordable, automotive companies are beginning to print end-use parts on-demand. This approach significantly reduces the need for mass production and storage of spare parts, paving the way for leaner, more efficient operations.

Indeed, the innovative prowess of 3D printing goes beyond mere manufacturing applications. Recently, automaker Local Motors stunned the industry by creating the world's first 3D printed car. The aptly named "Strati" took just 44 hours to print, announcing loudly the limitless potentials of this breakthrough technology in reshaping automotive production.

Artificial Intelligence: The Game Changer of the Automotive Industry

Integrating artificial intelligence in automotive manufacturing has revolutionized the industry. AI has not only made car production smarter but also introduced predictive capabilities into the entire manufacturing process, thereby reducing delays and boosting efficiency.

- Predictive Maintenance: By utilizing machine learning algorithms, manufacturers can predict potential machine breakdowns, schedule timely maintenance, and avoid costly downtime.

- Quality Control: AI-powered robotic systems are used to identify manufacturing defects with great accuracy. The technology can perform thorough end-to-end inspections, ensuring only the highest-quality vehicles leave the production line.

Without a doubt, AI holds immense potential in driving the next wave of advancements in the automotive manufacturing sector. Partnerships between car manufacturers and technology giants are increasingly common, clear indicators of a future where AI is entwined with every aspect of automotive production.

Lightweight Materials: Uplifting Automotive Efficiency

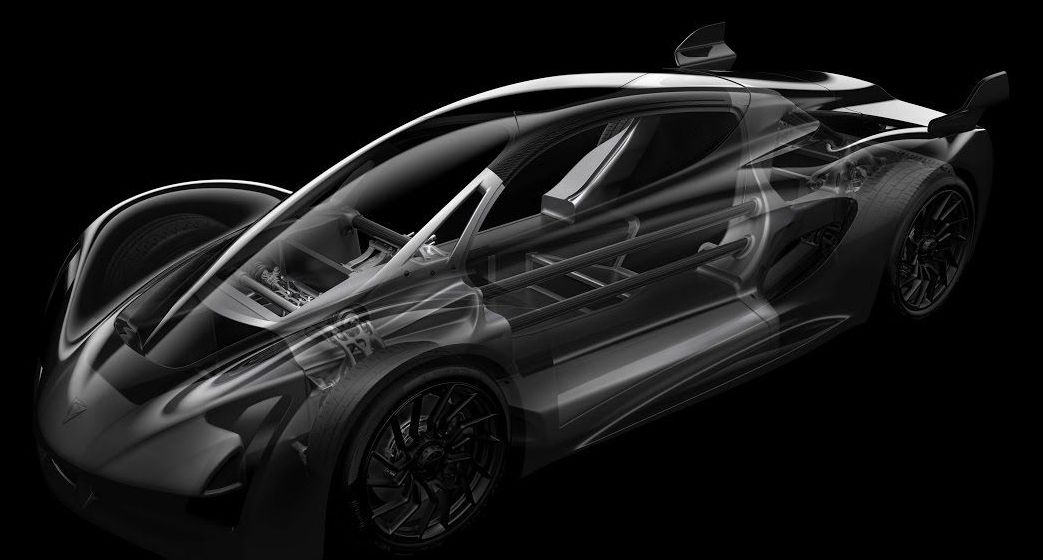

The drive for lighter yet stronger materials is another noteworthy innovation in automotive manufacturing. As regulations regarding fuel efficiency and emissions grow more stringent, using lighter materials is a potent weapon in an automaker's arsenal. Such materials not only help reduce a vehicle's weight, consequently improving fuel efficiency but can also enhance vehicle performance by promoting better handling and acceleration. The growing popularity of aluminum, high-strength steel, magnesium, carbon fiber-reinforced plastic (CFRP), and other composite materials has transformed both car design and manufacturing processes.

Advanced High-Strength Steel (AHSS): The Material of the Future?

The use of Advanced High-Strength Steel (AHSS) is a prime example of how automotive manufacturers are leveraging lightweight materials to their advantage. AHSS offers a perfect blend of strength and ductility, enabling manufacturers to build vehicles that are light yet robust. It has proven particularly useful in meeting safety standards, as its excellent crash energy absorption capacity improves the vehicle's crashworthiness.

Green Manufacturing: The Drive Towards A Sustainable Future

In an era supercharged with environmental consciousness, embracing green manufacturing techniques is no longer a choice but a necessity for automakers. Manufacturers are investing heavily in various environmentally-friendly practices and technologies, aiming to reduce their production's environmental footprint. Green operations are now viewed as an integral part of the manufacturing process, a critical component of corporate responsibility, and a significant selling point for eco-conscious consumers.

- Solar Powered Factories: Several manufacturers have shown a commitment to sustainability by powering their factories using renewable energy sources. Tesla, for one, operates its famous ‘Gigafactory’ in Nevada largely on solar power.

- Recycling and Resource Efficiency: The efficient use and recycling of resources have become more important than ever. Automakers are now using more recyclable materials and implementing processes aimed at minimizing waste.

- Emission Control: Technological advancements in emission control, such as the adoption of cleaner fuels and electric energy, are being embraced by manufacturers. These not only reduce air pollution but also help automakers meet continually rising emission standards.

It’s clear that the world of automotive manufacturing is evolving rapidly, and green manufacturing is aligning the industry with global sustainability goals. Expect to see these innovations becoming more mainstream as the industry moves towards a cleaner and greener future.

Conclusion

The automotive manufacturing landscape has undergone a significant transformation, fueled by these five key innovations. Automation, 3D Printing, Artificial Intelligence, Lightweight Materials, and Green Manufacturing have all contributed to enhancing efficiency, reducing costs, and promoting sustainability. While these advances have already made a considerable impact, there’s no doubt that they will continue to mold the future of automotive production and push the boundaries of what is conceivable in vehicle manufacturing.

Here at AutoInsiderHub, we’re excited to track these innovations and keep you updated on the latest trends and breakthroughs from the automotive world. As we continue to drive insights into the automotive sector, we invite you to keep pace with us as we journey together into a thrilling future shaped by technological innovation.

What's Your Reaction?